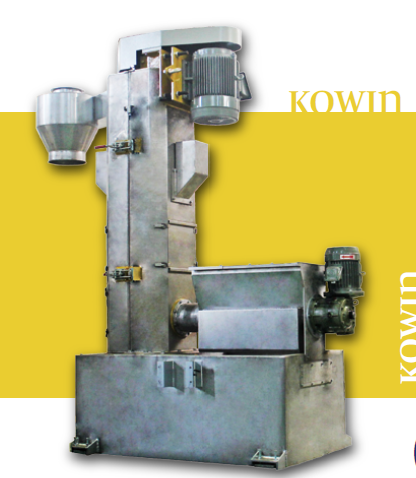

Centrifuge

Centrifuge

Patented centrifuge with an openable design. Easy maintenance and cleaning, saving time changing materials. Machinery patented worldwide.

Material (after crushing): Blow molding, bottles, containers, injection products, extrusion lumps, sheets and tubes, vacuum forming and pressure forming products, shoes, sneaker soles, dirty plastic pellets... etc.

This machine has been well designed by KOWIN and achieves the purpose of being easy to use and beneficial. Specially designed draining blade. High drainage rate. The moisture content of non-foamed plastic material after centrifugation is less than 3% and can be sent directly to the extruder to make granules. The special draining blade design also reduces gunpowder production. Automatic operation saves labor and electricity costs by 30%. The machine operates continuously 24 hours a day, 365 days a year.

Patented material discharge design. No material jams guaranteed. Capacity increases.

Features of the KOWIn centrifuge

- Centrifuge - Openable Design. Unlike conventional centrifuges, which are non-openable, the KOWIn centrifuge is much easier to clean and maintain.

- The moisture content of non-foamed plastic material after KOWIN centrifuge should be less than 3% and can be sent to extruder to make pellets directly.

- Continuous operation 24 hours a day, 365 days a year. Automatic control, saving labor and electricity costs by 30%.

- Environmentally friendly machinery. The KOWIN centrifuge saves energy costs and reduces CO2 emissions more than other machines.

drainage machine.